Rent a pump with accessories

Renting a wobble ring pump is a practical solution for companies that need a powerful pump temporarily or temporarily.

Industrial pumps for rent is a practical solution for companies that, temporarily or temporarily, have powerful Need a pump. In Germany, there are a variety of pump manufacturers who offer industrial pumps for rent. These pumps are specifically designed for use in industrial environments and can be used for various applications, such as pumping out water, pumping dirt or circulating liquids.

When renting a industrial pump Is it important to also the right accessory Rent as well. This may include, for example, hoses, valves, filters or connections. The accessories are crucial to be able to operate the pump efficiently and safely.

We from pumpsystems give you the opportunity to industrial pumps and to rent the appropriate accessories conveniently and reliably.

About our rental pumps

This includes a lot — from hoses and pipes to control systems and spare parts. We have everything you need for a smooth operation of your industrial pump require.

Our professional team is here to help you select the right pump technology to the side. Wir counselled Please tell us which pump is best suited to your specific requirements. In doing so, we take into account factors such as flow rate, suction height and type of liquid to be pumped.

In addition, we also offer you the Service the installation and commissioning of the rented industrial pump. Our experienced technicians ensure that the pump installation and subsequent pump operation go hand in hand. We also take care of the regular servicing and upkeep and necessary repairs to ensure smooth operation.

With our flexible rental model You can rent the industrial pump for the period you need. Whether for short-term needs or long-term projects, we adapt to your individual requirements.

Contact Contact us today and let our professional team advise you. We are happy to help you and work together to find the best solution for your individual requirements.

Rent the wobble ring pump with accessories

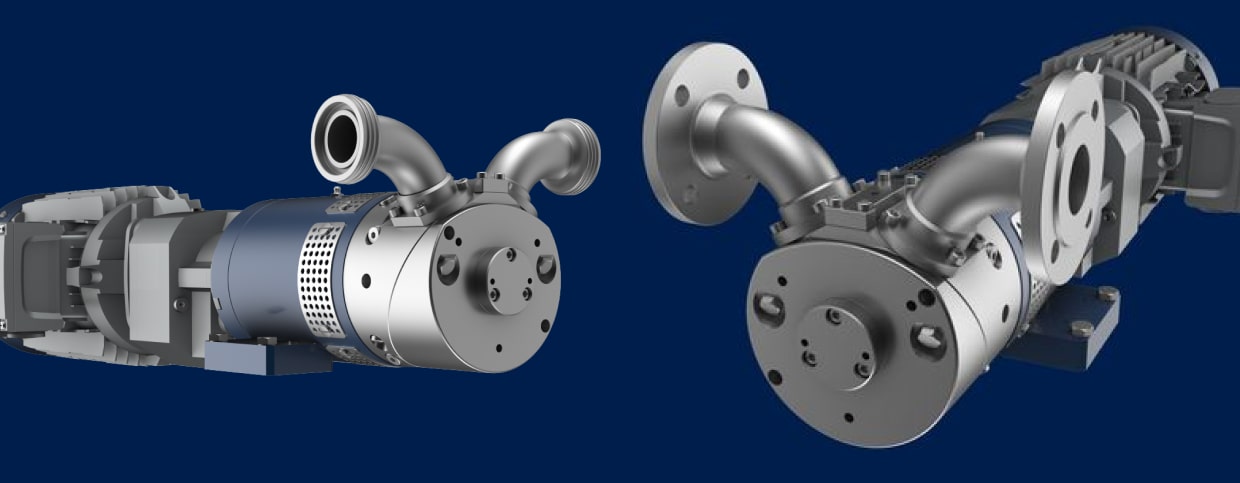

Die wobble ring pump Renting is a good option for companies that efficiency and reliability needed for various applications. This type of pump is widely used in industry and is used in a wide range of applications.

One of the main advantages of the wobble ring pump is its ability to both viscous liquids as well gasses to promote. This makes it a versatile option for various applications.

Die How it works The wobble ring pump is based on the oscillating rotor, which rotates within the housing. This rotor consists of several rings that move around it and form a kind of seal. When the rotor rotates, a vacuum is created which sucks in the liquid or gas.

As soon as the rotor continues to rotate, the medium is compressed and released through the outlet. This process enables continuous delivery of the medium without interruptions. The wobble ring pump is working energy efficient and quietly.

It is important to note that the wobble ring pump must be serviced regularly in order to achieve an optimal conveying capacity to ensure. This includes checking and, if necessary, replacing the pump components to prevent leaks. Regular inspection and cleaning of the rotor is also required to remove debris and ensure smooth operation.

The accessories of the wobble ring pump play a particularly important role here in ensuring optimum performance. These can include, for example, pressure regulators, filters, but also spare parts such as wobble rings or seals. These components can Pump efficiency improve and extend the life of the pump at the same time.

When you rent a wobble ring pump, you should make sure that you have the right sized and power choose to meet your requirements. There are different models and variants to choose from, depending on the type of medium you want to pump and the level of efficiency required.

You can find out more about this in our product brochures.

How do you find a suitable industrial pump?

There are various steps you can follow to find a suitable industrial pump.

First, you should precisely define the requirements and needs of the respective industrial application.

What type of liquid or material must be pumped?

Different liquids and materials are used in various industrial sectors. For example, in the chemical industry often conveying aggressive and corrosive liquids, such as acids or bases.

In the food industry On the other hand, we often viscose and sensitive liquids, such as cream or chocolate, are transported.

Even in the pharmaceutical industry There are special requirements for pumping liquids. Sterile and ultra-pure liquids, such as drugs or solutions, must often be transported here.

What flow rate and delivery height are required?

flow rate includes the amount of material or liquid that is to be pumped per unit of time. It is expressed in liters per hour, cubic meters per second, or other units. The exact flow rate depends on various factors, such as the size of the container, the desired flow rate and the type of material to be transported.

Die Conveyor height On the other hand, describes the pressure with which the material or liquid is to be delivered. It is expressed in meters or bar and indicates how high the pumped medium must be pumped against gravity or other resistances.

In order to determine the required flow rate and delivery level, it is important to consider the specific requirements of the project. This includes the type of material, the distance over which it is to be conveyed, and the desired speed of conveying.

Are special features such as Pressure resistance or temperature tolerance required?

This means that the pump construction must meet certain requirements. In many cases, it is necessary for the material to be pressure-resistant to meet the requirements of various industrial applications. It may also be necessary for the material to have a high temperature tolerance to withstand the extreme conditions in certain environments.

In the German language, the term “pressure resistance” is often used to describe the ability of a material to printing to withstand. This is particularly important in areas such as mechanical engineering or the automotive industry, where components can be exposed to heavy loads.

Die temperature tolerance is another important aspect that must be considered when choosing a material. In some applications, high temperatures occur, whether as a result of friction, chemical reactions, or other factors. The material should be able to withstand these temperatures without altering or damaging its properties.

It is also possible that special properties such as corrosion resistance or electrical conductivity is required. Depending on the application, these properties can be of great importance and must therefore be taken into account when selecting materials.

Which industrial pumps are there?

Next, you should consider the various pump types Get to know. There are various types, which can be roughly divided into centrifugal pumps and positive displacement pumps. Each type has its own advantages and disadvantages, depending on the specific requirements of the application.

centrifugal pumps For example, work by centrifugal force, which pushes the fluid outwards from the center of the pump. These pumps are generally efficient and have a high flow rate. They are well suited for applications where large quantities of liquid must be transported at low pressure.

positive displacement pumps On the other hand, work through the principle of volume change. They use pistons, gears, or membranes to capture the fluid and then push it through the pump. These pumps are ideal for applications where a constant pressure or an accurate flow rate is required. They may also be suitable for viscous liquids or abrasive materials.

The positive displacement pumps also include the wobbling ring pump. It is characterized by its high efficiency and ability to work even at high pressures.

After learning about the different types of pumps, you should weigh the advantages and disadvantages of each type and choose the one that best suits the specific requirements of the industrial application.

We are happy to help you with Choose your rental pump. Contact us and find out more about the various Models and sizes our wobble ring pump, which are available for short-term and individual rent.