Industrial pumps for hydrocarbon extraction and processing

Industrial pumps for extracting and processing hydrocarbons are of great importance in the oil and gas industry.

industrial pumps for the conveying and processing of hydrocarbons are of great importance in oil and gas industry.

These pumps have been developed specifically for the requirements of the industry and are characterized by their high performance, reliability and durability. They can contain large amounts of hydrocarbons such as petroleum, natural gas and Charcoal liquids promote while maintaining constant pressure.

Especially pumpsystems Wobble ring pumps are able to handle large flow rates and ensure continuous delivery. These systems are often used in refiners, pipelines and petrochemical plants are used.

Selecting the right industrial pump is crucial for the smooth operation and efficiency of the conveyor and processing processes. There are various types of pumps, which are suitable for various applications, such as centrifugal pumps, screw pumps and piston pumps.

About our industrial pump for hydrocarbons

What are hydrocarbons?

Hydrocarbons are chemical compounds that consist of carbon and hydrogen atoms. They are in the organic chemistry of great importance and form the basis for many organic compounds. Hydrocarbons can be divided into different classes, depending on how the carbon atoms are bonded together.

An important class of hydrocarbons is alkanes. alkanes consist of a chain of carbon atoms that are simply connected to hydrogen atoms. They are saturated compounds as they contain no double or triple bonds. Alkanes are generally present in nature as crude oil or natural gas and serve as fuels.

Another class of hydrocarbons is Alkene. Alkene contain at least one double bond between two carbon atoms. This double bond gives alkenes increased reactivity compared to alkanes. Alkenes are often used as starting materials for the synthesis of plastics.

There is also the Alkine, which contain at least one triple bond between two carbon atoms. Alkine are even more reactive than alkenes and are often used in organic synthesis.

In addition, there are other classes of hydrocarbons, such as aromatics, which have a special ring-shaped structure, as well as many other complex compounds.

Die properties hydrocarbons depend on their structure. Depending on the number and type of bonds between the carbon and hydrogen atoms, they can have different physical and chemical properties. For example, alkanes have low reactivity due to their saturated structure and are generally not polar. Alkenes, on the other hand, are more reactive due to their double bond and can participate in chemical reactions such as addition.

Where are hydrocarbons used?

Hydrocarbons are used in many different areas. An important area of application is energy production. In Germany, hydrocarbons such as crude oil and natural gas are used to generate electricity in power plants. They serve as fuels to generate heat and drive turbines.

Another important area of use for hydrocarbons is chemical industry. Here they are used as starting materials for the production of plastics, dyes, solvents and many other chemical products. The versatile properties of hydrocarbons make it possible to produce a wide range of materials that are used in various industries.

Hydrocarbons also play a decisive role in the transport sector. petrol, diesel and kerosene, which are derived from hydrocarbons, are the main fuels for cars, trucks, airplanes and ships. They make it possible to operate vehicles and machines with a high level of energy efficiency and to cover long distances.

In addition to these main applications, there are many other areas in which hydrocarbons are used. For example, they are called lubricants used in industry to reduce friction and wear. In agriculture, too, they are used as plant protection products used to control pests and increase yields.

Overall, hydrocarbons play a central role in our modern society and have become an integral part of many areas. Demand for these versatile connections will continue to rise in the future, as they provide an important basis for industrial production and form a daily lifestyle.

Which industrial pumps are suitable for pumping and processing hydrocarbons?

When choosing industrial pumps There are various factors to consider when extracting and processing hydrocarbons.

First, the pumps should be off materials be produced which are resistant to the properties of hydrocarbons. This is important to prevent corrosion or damage to pump components. Pumps made of stainless steel or special alloys, which have a high resistance to hydrocarbons, are usually used.

It is also important that the pumps have a high conveying capacity to meet the requirements of hydrocarbon processing. This includes the ability to produce large quantities of liquids or to efficiently pump sludge.

Another aspect is the type of hydrocarbons that are to be extracted and processed. Depending on whether it is liquid hydrocarbons such as crude oil or gaseous Hydrocarbons such as natural gas may require different types of pumps. For example, centrifugal pumps are good for pumping liquid hydrocarbons, while positive displacement pumps are suitable for pumping viscous liquids such as bitumen.

In addition, it is advisable to select pumps that have integrated safety devices in order to minimize potential risks. This may include, for example, the use of explosion-proof motors or pumps with leak detection systems.

Ultimately, when selecting industrial pumps for the extraction and processing of hydrocarbons, the servicing and maintenance are taken into account. It is important that pumps are easily accessible and have simple maintenance procedures to minimize downtime.

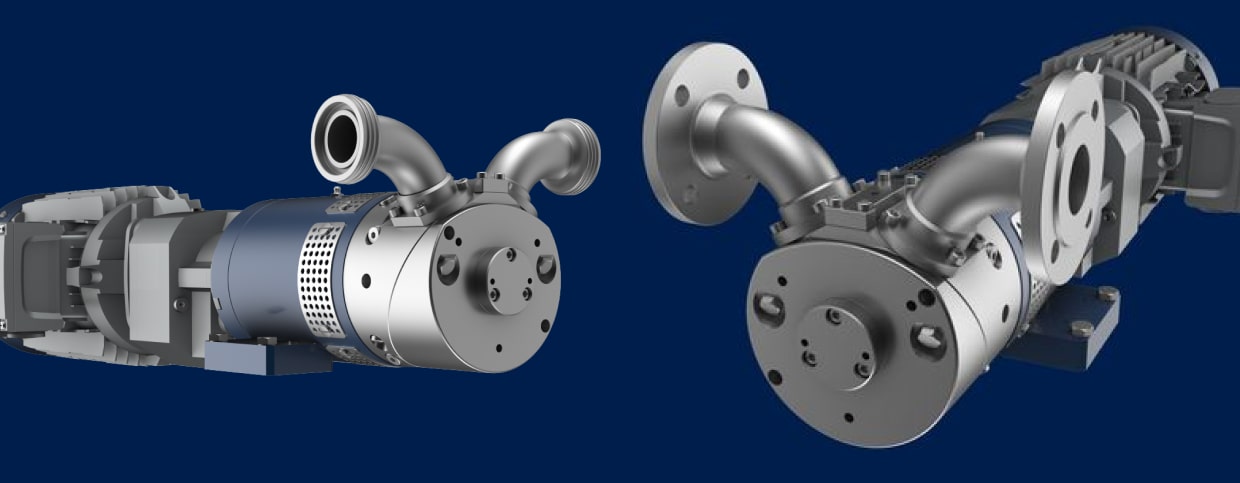

The wobble ring pump for pumping hydrocarbons

Die wobble ring pump is an efficient and reliable solution. With its robust construction and powerful motor, it enables effective pumping of hydrocarbons in various industrial sectors.

The wobble ring pump works on the principle of wobbling, in which a ring with several chambers rotates around a fixed cam. As a result of this movement, a continuous flow rate which transports hydrocarbons safely and efficiently through the system.

Thanks to their high performance and ability to also viscous liquids To pump, the wobble ring pump is ideal for use in the oil and gas industry. It can easily handle various types of hydrocarbons, such as crude oil, natural gas or diesel.

In addition, the wobble ring pump is characterized by its low maintenance requirements. The robust construction and high-quality materials ensure a long life and minimize the need for regular repairs or replacement of components.

The wobble ring pump is often used in tank farms, refineries, petrochemical plants and used in other industrial applications. It is a proven solution for the efficient and safe extraction of hydrocarbons and contributes to the optimization of production processes.