Application and function of diaphragm pumps

Diaphragm pumps ensure easy handling, particularly with demanding media.

Die How it works The diaphragm pump is fundamentally reminiscent of the human heart. The contracting muscles of our heart, which pump our blood, represent the membrane here. Die membrane determines and generates the pumping process. It ensures pumping process shielded from external influences.

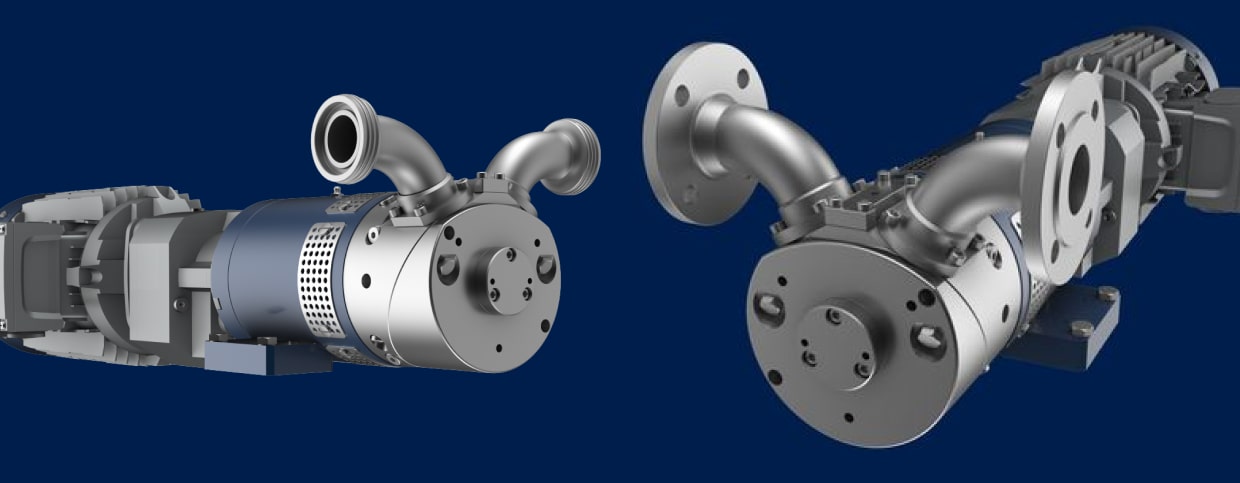

What is a diaphragm pump?

A diaphragm pump is a pump that is very popular. It enables leak-free pumping process. Due to its easy handling and use and its invulnerability, it is also used in the chemical industry very popular. Also a continuous stress is no problem for the diaphragm pump.

Diaphragm pumps belong to the group of positive displacement pumps with reciprocating piston drive. Displacement pumps belong to type of pump, which work with the displacement principle. Sometimes referred to as volumetric pumps.

Zu unseren Industriepumpen

What are positive displacement pumps?

All positive displacement pumps pump a medium in a closed cavity. The so-called displacer creates periodic volume changes in the interior. As a result, the promoted substance Added energy. This energy is produced by two or sometimes three spindles, each moving in the opposite direction. that pumping medium It is expanded on the suction side and contracted on the pressure side. This ensures that the volume remains constant, as do the outlet pressure, input vacuum and liquid properties. Because they are self-priming and have strong suction on the suction side, they are generally easy to maintain and handle.

A distinction is made between two different types of positive displacement pumps. There is rotating pumps and pumps with reciprocating piston drivejust as the diaphragm pump is one.

Within a reciprocating piston driven positive displacement pump A so-called hub is created. The stroke is a movement that is repeated at regular intervals. As a result, the flow is pulsating, which makes it ideal for precise dosing of the pumped medium. In addition to the diaphragm pump, types of reciprocating-operated positive displacement pumps are also piston pumps Or even plunger pumps.

Die piston pump contains a cylinder in which a piston retracts and expands again. If it retracts, the volume gets in, it expands again, back into the cylinder, the valve at the outlet opens and the medium can escape.

plunger pumps They work in a very similar way and are almost identically constructed. The so-called plunger moves through a seal into the Medium. This changes the volume within the pump. If the plunger now moves out of the interior again, it produces the desired pumping effect due to the brief change in volume.

Within rotating positive displacement pumps rotating gap seals function as separators. These control a delivery flow with the rotational movement of the displacer body. Types of rotary positive displacement pumps are rotary lobe pumps or even outdoor and internal gear pumps.

Die external gear pumps, which are the most frequently used gear pumps, typically have two gears. These lie on shafts which are connected to a motor. If you turn these gears one into the other, you transport the medium into the cavity and between the gears. As a result of the direction of rotation of the gears, the pumping mechanism the medium to the outlet.

internal gear pumps They also have two gears, which, however, are of different sizes and have different numbers of teeth. They lie one inside the other and this creates internal interlocking. They rotate into each other and through a crescent-shaped sealing In the interior, the medium reaches the interior of the pump. When the inner gear wheel rotates over the seal again, the volume discharges again.

rotary lobe pumps Similar to the external gear pump, they also have two rotating elements. In the case of rotary lobe pumps, however, they are rotary pistons instead of gears. The way it works is very similar. A motor with gears drives both rotary pistons and the pumping medium gets into the pump and out again. The reduced contact between the two rotary pistons prevents wear and allows solids be better promoted.

How does a diaphragm pump work?

Die diaphragm pump has a membrane that flexibly bends inwards and outwards. The membrane, also known as a diaphragm, vibrates. This creates a vacuum which enables the pumped medium to flow in and out. When the membrane bends outwards, does the flow Conveyor goods inside. Subsequent when the separating membrane When it bends inwards again, it transports the medium into the outflow channel. This membrane consists of a highly chemical-resistant and also tear-resistant, elastic material. In order to exploit their full potential, several diaphragm pumps are traditionally connected one after the other. This results in a useful vacuum. As a result of the gases expelled in the first chamber being absorbed by the second chamber.

Where are diaphragm pumps used?

This pumping technology allows pumping of abrasive fluids Or even dangerous slurry. With a diaphragm pump, there is no risk of running dry, and a leak-free pumping experience is also possible. It easily conveys liquid substances or even gases.

One continuous stress It's also no problem and the membrane separates toxic chemicals. At the same time, it shields the medium from external influences. As a result, it is very popular with stake in the process engineering and chemical engineering. It is also often found in food technology. If you would like to know more about pumps in the food industry Or else the chemical industry Please feel free to read our other articles.

Diaphragm pumps are available in a wide variety of drive types and therefore have a very different Scope of application. A distinction is made between Compressed air diaphragm pumps, mechanical diaphragm pumps, hydraulic diaphragm pumps, pneumatic diaphragm pumps and electromagnetic diaphragm pumps.

Mechanical diaphragm pumps are characterized by the fact that they have very low energy consumption. A common example of this is the hand-operated diaphragm pump with a classic bellows. The lever must be pushed up and down manually. Through this vacuum generation The membrane vibrates.

Die hydraulic diaphragm pump works with a piston, which is operated by a motor. Hydraulic oil prevents the duration of action from being distributed. Known hydraulic diaphragm pumps are piston diaphragm pumps.

Die pneumatic diaphragm pump, which is operated by a pneumatic cylinder and pneumatic valves, has a high energy consumption. The pneumatic valves generate compressed air and the cylinders convert it into energy.

At the electromagnetic diaphragm pump An electrical coil moves the membrane. This current creates a magnetic field. This causes the piston to move. When the power goes out, the piston retracts again. This results in movement in the membrane.

Just as wide-ranging is the Field of application our wobble ring pump.

Feel free to browse through our brochure and see for yourself.

Here you can learn more about the different pump types Or their eligible substances.