Application and function of pumps in the pharmaceutical industry

The pharmaceutical industry has been with us humans for a very long time. It generates several billion euros annually.

Die pharmaceutical industry is an important sector of the healthcare industry. In Germany, around 300 companies are active in this sector. The range of applications includes the development, production and distribution of Pharmaceuticals. The sector employs around 140,000 people.

How long has the pharmaceutical industry existed?

Humanity has been experimenting with medicines since an estimated 3000 BC. The first traditions of efficacy most diverse active ingredients comes from the Sumerians in Mesopotamia and dates back 5000 years. The recipe collections from back then were based purely on experience and a few lucky coincidences.

The Egyptians, who were far ahead of their time, also left behind the well-known Ebers papyrus about 3500 years ago. It records 880 medical remedies and prescriptions. Some of this knowledge was also required during mummification.

During its creation period, medicines exclusively plant-based. Only later were others added, which were of animal and mineral origin.

The first pharmacies were built around the 9th century.

In the Middle Ages and Antiquity, there were two places of contact for people with medical concerns. These were on the one hand the doctor and on the other hand their own home pharmacy. In doing so, they had medicines ingredients similar to the medical prescriptions and also the small home remedies.

Unfortunately, medical knowledge disappeared for a few years after the fall of the Roman Empire. Now it was the monks who gave their modulus for the development of healthcare performed. They could translate the traditional writings with the knowledge of pharmacy.

As a result, monks acted equally as doctors and pharmacists. They provided people with their knowledge of medicinal herbs. As a result, spice retailers also specialized and now also offered some of their goods for healing purposes. Very high demand finally led to the job profile of drug manufacturer established.

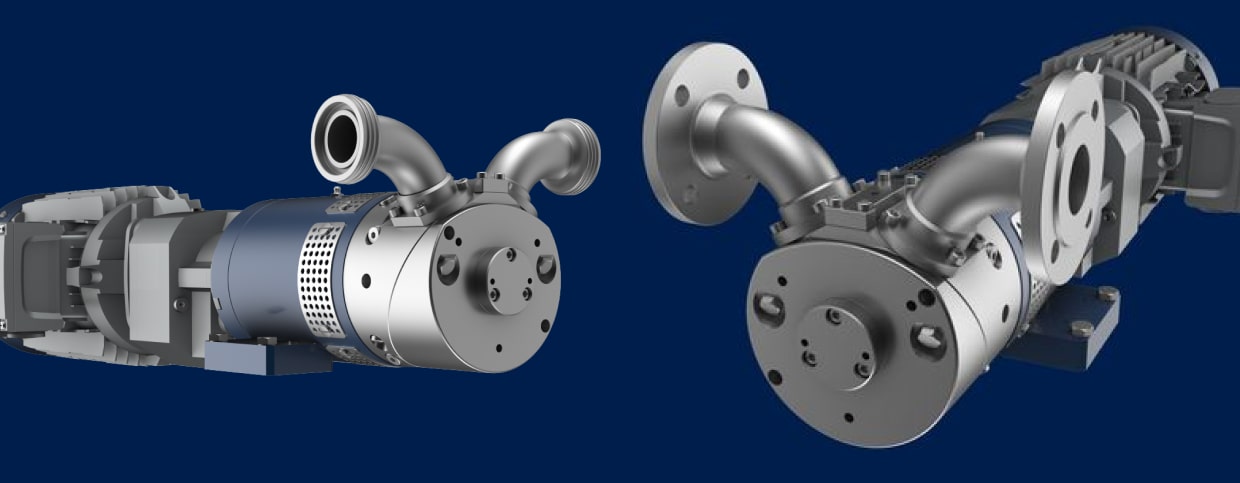

About our pumps for the pharmaceutical industry

The pharmaceutical industry in Germany

that health care system in Germany is based on the pharmaceutical industry. With the help of pharmaceutical companies various diseases can be treated well. Some vaccines effectively curb the severe course of many diseases. This includes, for example, cancer, HIV or even corona. The pharmaceutical industry is constantly growing and has many jobs. It generates annually around 43 billion euros. Of which it reinvested 13.2 percent in research in 2018. This makes it a leader in this sector and is ahead of the chemical or automotive industries.

Pumps in the pharmaceutical industry

Especially for pharmaceutical companies Good and suitable pumps play a very important role. Hygiene standards must be strictly met and the relevant certificates must be available. This includes, for example, so-called FDA approval of medical devices or EHEDG certification. Other certifications include the GMP Directive (75/319EEC) or the ASME-BPE certification. The EU Machinery Directive (2006/42EG), DIN EN 1672-2 (for food processing machines — safety and hygiene requirements) and finally the DIN EN 12462 on biotechnology (performance criteria for pumps) must also be available.

More about the marketing approval of drugs from Federal Ministry of Health find here.

Even with the quality of the water, the production of Medicinal productl. To ensure good water quality, the right pump must be carefully selected. The pump must use the water in accordance with the requirements for ultrapure water Or even Water for injections be able to process. Stainless steel is best for a sterile pumping experience and the housing should be flow-optimized. The appropriate expertise in pumps and their operation is just as crucial for the smooth production process of pharmaceuticals. Easy handling, functionality even under continuous use and good and quick cleaning are essential here.

The media that are pumped must be transported through the pump almost without pulsation. Dosing accuracy, even with abrasive or highly viscous media, is an equally important factor when choosing a pump.

Requirements for the ideal pharmaceutical pump

Choosing the ideal pump is very important in the pharmaceutical industry. According to the width Field of application There is a wide selection of suitable pumps.

In addition to easy maintenance and availability, easy and quick cleaning is the main goal. Pumping systems must be built in accordance with the “Hygienic Design” requirements. This helps to keep cleaning costs low. It is essential to ensure complete emptying of residual material. If the cleaning process becomes more complicated, water consumption and time are significantly increased, and competitiveness and manufacturer company faces additional costs.

It is also important that pipelines, pumps, valves and fittings do not counteract the drugs. It is important to consistently prevent organic and inorganic contamination.

In order to support problem-free cleaning, dead spaces must be prevented and a gap-free design must be possible.

If the medium touches surfaces, there must be no surface damage, such as cracks or scratches. Because they provide an ideal habitat for bacteria. A helps with this electro polish, which improves corrosion resistance and durability. It also results in a significantly smoother surface.

But it's not just the pump itself that needs to be hygienic. Seals and connections must also comply with “Hygienic Design” standards.

The seals should be encapsulated and can be flushed freely. In addition, the material must be durable and also able to withstand cleaning.

In the pharmaceutical industry, too, a wide variety of positive displacement pumps or centrifugal pumps of all types have proven their worth. Substances such as infusion solutions, suspensions, nutrient solutions, alcoholic solutions, vaccines, blood plasma or ointments are most commonly pumped. In the production of medicines Pumping water also plays an important role. The quality of the water to be pumped is divided into water for injection purposes WFI, purified water PW or distilled water AP.

Dominate right now centrifugal pumps the pharmaceutical market. They meet all requirements of pumping technology in terms of easy handling, easy cleaning and all hygiene standards. However, in the case of highly viscous liquids They may have problems. They are recommended with a viscosity of up to around 500 mPas, anything above that is more likely to be problematic.

With this problem, the positive displacement pumps used. Depending on how high the motor speed is, the positive displacement pumps deliver a defined volume regardless of pressure, viscosity and solid content.

Even with gentle conveying of sensitive Active pharmaceutical ingredients Rotary lobe pumps, for example, offer a solution thanks to their almost pulsation-free delivery. Abrasive media can also be pumped using positive displacement pumps.

A good solution is also offered by our wobble ring pump, which high flexibility delivers and meets all requirements for a pharmaceutical pump. You can find out more about this in our Product brochure and on our webpage. After a brief consultation, we also offer the opportunity to borrow and try out the pump. Feel free to call us during our Opening hours and get an idea of our offers.

Here Learn more about the use and function of pumps in the cosmetics industry.