Temperatures of the transportable liquids of industrial pumps

This article provides information on the various aspects of pump technology and selection with regard to temperature requirements.

Die temperatures The transportable fluids from industrial pumps play a decisive role in efficiency and power of these devices. It is important to understand the various aspects of pump technology and selection in terms of temperature requirements. This is the only way to ensure smooth operation and a high level of operational safety.

One of the key components when choosing an industrial pump to handle high temperatures is the Material selection. The pumps must be made from corrosion-resistant materials to minimize the impact of hot or aggressive liquids. Corrosion resistance is crucial for pump longevity and low maintenance requirements.

Die viscosity The liquid to be pumped also plays an important role. The higher the viscosity, the more power consumption and speed are required to achieve the desired flow rate. This can affect the efficiency of the pump and lead to an increased pressure loss.

Another important factor is NPSH value (Net Positive Suction Head) This indicates how much pressure must be present at the pump inlet to prevent cavitation. Cavitation can damage the pump and impair operating behavior.

Die pump characteristic is a graphical diagram which shows the operating behavior of the pump in terms of delivery height, flow rate and delivery pressure. This diagram is crucial to understand the pump's performance at different temperatures and to select the optimal operating point.

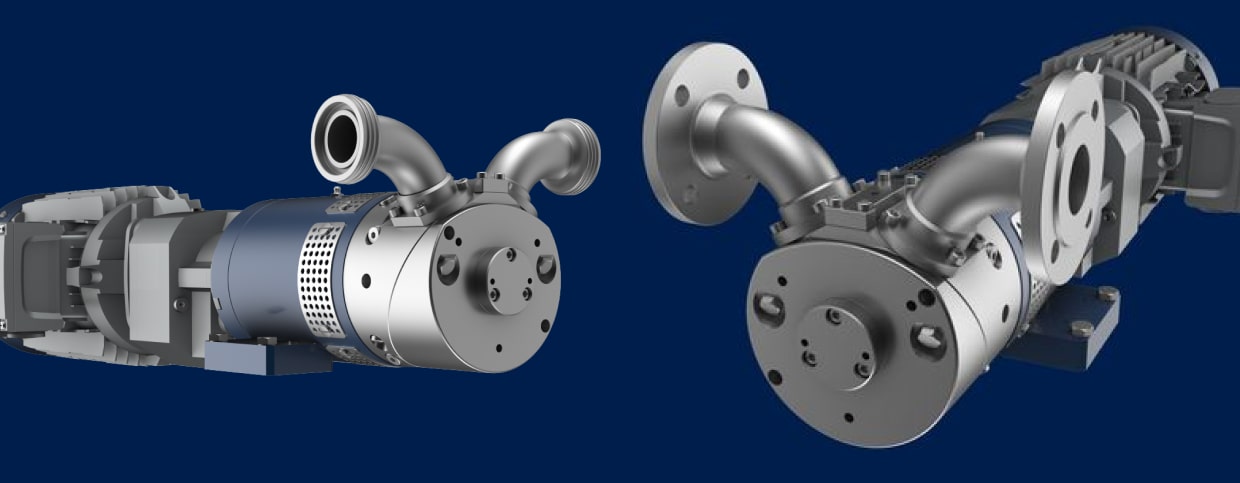

The choice between different pump types is also important. In addition to the wobble ring pump, which can pump up to 200 degrees Celsius, other types of pumps are also used for high temperatures.

About our pumps for high-temperature environments

What temperatures can our wobble ring pump deliver?

The pumpsystems ring pump system can pump temperatures of up to 200 degrees Celsius.

In addition, it is important to note that our wobbling ring pump is specifically designed for use in high temperature environments was developed. It offers excellent performance and reliability, even at extreme temperatures. Whether it's industrial applications, chemical processes or other demanding environments, our wobble ring pump is able to withstand high temperatures and to deliver them efficiently.

What is the maximum temperature that pumped media may have?

As a rule, industrial pumps can pump media with temperatures of up to 120 Handle degrees Celsius without any problems. However, the temperatures vary significantly depending on the type of pump.

Some pump models are specifically designed to handle higher temperatures and can handle pumping media of up to 200 degrees Celsius. These high-temperature pumps are usually equipped with special materials and seals equipped that can withstand high temperatures.

However, it is important to note that the maximum temperature limit for each pump model is set by the manufacturer. It is advisable to consult the technical data sheets of the respective pump to determine the exact temperature limits to determine. To ensure the specified performance and longevity of the pumps, it is advisable to follow the manufacturer's instructions. Otherwise, serious damage to the pump may occur.

In addition, it is important to consider the type of pumping medium. Some media can at high temperatures corrosive and impair the life of the pump. In such cases, it is advisable to use special corrosion-resistant pumps designed to handle such media.

What types of pumping media are there and what are their temperatures?

There are various types of pumping media used in industrial pumps, and their temperatures may vary depending on the application. Here are a few examples:

1. water: Water is one of the most common pumping media for industrial pumps. The temperatures can range from cold water that is close to freezing to hot water that can reach over 100 degrees Celsius.

2nd oil: Oil is often used in industrial pumps, particularly in applications that require lubrication. The temperatures can range from room temperature to high temperatures of over 200 degrees Celsius, depending on the type of oil used.

3rd chemicals: Depending on the type of chemical, temperatures in industrial pumps can vary significantly. Some chemicals require low temperatures while others can be handled at high temperatures. It is important to follow the specific temperature requirements for each chemical.

4th vapour: In some industrial processes, steam is used as a pumping medium. Steam temperatures can be very high, ranging from 100 degrees Celsius to several hundred degrees Celsius, depending on the application.

Which pumping media can be pumped with our wobble ring pump?

Our wobble ring pump can transport a wide range of pumping media. This includes liquids such as water, oils, solvents, and chemicals. In addition, it is also able to transport viscous media such as lubricants, paints and varnishes. Even abrasive media Such as mud and sand, can easily be transported by our wobbling ring pump. With its robust design and reliable operation, it is the ideal solution for many industrial applications.

Which pumps are also used for high temperatures in addition to the wobbling ring pump?

A commonly used type of industrial pump for high temperatures is the centrifugal pump. These pumps work with an impeller, which pumps the liquid through centrifugal force. centrifugal pumps can generally handle temperatures of up to 200 degrees Celsius and are therefore ideal for applications in the chemical industry or in food processing where high temperatures are required.

Another type of industrial pump that is suitable for high temperatures is the screw pump. These pumps use a screw thread to deliver the liquid. They are able to handle temperatures of up to 300 degrees Celsius and are often used in the oil and gas industry.

For extremely high temperatures above 300 degrees Celsius, special pumps such as magnetic clutch pumps or gear pumps used. These pumps use magnetic or mechanical couplings to deliver the liquid and are equipped with heat-resistant materials and seals.

It is important to note that operating industrial pumps at high temperatures requires additional safety precautions. Heat-resistant materials and seals must be regularly checked and waited to ensure safe and efficient operation of pumps.

In addition, it is important to pay attention to the operating temperature of the pump itself. High temperatures can affect the life of the pump and lead to premature wear. The manufacturer's instructions on the maximum operating temperature should therefore be strictly observed.

How cold can a pumped medium be?

As a rule, the cold of the pumped medium should not be below freezing point lie down. This is particularly important to prevent blockages or damage to the conveyor lines. At lower temperatures, there is a risk that the medium will freeze and thus impede the flow.

In addition, it is important to consider the specific requirements of the pumped medium. Some media, such as certain chemicals or foods, can change their properties or even become dangerous at extreme temperatures.