Pumps for mashed raw materials

The extraction of crushed raw materials presents pumping systems with several challenges.

Pumps play a crucial role in workmanship crushed raw materials in various industries, in particular in food and beverage industry. A special type of pump that is frequently used in this context is the wobbling ring pump. In this text, the function and role of the wobbling ring pump in crushed raw materials is examined in more detail.

One pump is a device that moves liquids or gases by generating pressure and transporting them through a system of pipes. In the case of crushed raw materials, the challenge is to efficiently and gently convey a viscous, porridge-like mass.

Pumps for mashed raw materials

What are mashed raw materials?

Crushed raw materials is a term used in connection with the production of food. “Mashed” means that a specific raw material is processed into a mash or mash made from other ingredients. This process is often used in manufacturing used by alcoholic beverages such as beer or whiskey.

In beer production, for example, malt is mashed in order to enzymatic to enable starch to be converted into sugar. The malt mash is then cooked and hops are added to develop the desired taste and aromas. After fermentation, the beer is finally bottled.

Whiskey is mashed in a similar way. A combination of malted barley and other grains is made into a mash, which is then is fermented and distilled. The mashed raw material, the mash, is decisive for the taste and quality of the finished product.

It is important to note that the term “crushed raw materials” can be used in various contexts. It is not limited exclusively to alcoholic beverages. In the food processing It can also be used on other types of raw materials to produce various products. This can be the case, for example, when making a mash of bread, sauerkraut or pickled vegetables.

In the chemical industry Mashed raw materials are also used to produce products such as cleaning agents or paints. The raw materials are processed in a process similar to alcoholic fermentation fermentedto process them into a final product.

In summary, crushed raw materials are an important component in the production of foodstuffs, in particular alcoholic beverages such as beer and whiskey. Through the Mash process The desired aromas, flavors and texture profiles can be developed to produce high-quality end products.

What must be considered when choosing the pump for mashed raw materials?

Mashed raw materials pose a particular challenge due to their viscous and mushy consistency. There are therefore a number of factors to consider when choosing a suitable pump for this purpose.

An important feature that a pump should have for handling crushed raw materials is a robust construction. Since this versus abrasives The material must be durable. The pump must be able to handle possible solids or fibers that may be contained in the raw materials.

Furthermore, the pump's ability to gentle Promoting the masses is of great importance. The crushed raw materials should be exposed to as few shear forces or pressure fluctuations as possible during the pumping process. Careful conveying is crucial to prevent a change in its consistency or quality.

Another aspect that should be considered when choosing the right pump is its ability to adapt to different degrees of viscosity. Depending on the type of product and the manufacturing process, viscosities can vary significantly. The pump should be able to work with different Consistency levels in order to ensure efficient funding.

In some cases, control of flow and pressure be important. This can be achieved by using throttle valves or valves to regulate the flow of crushed raw materials and adjust the pressure to an optimal level.

When handling crushed raw materials, it can also be useful to think about ways to monitor and control pump performance. This can be done by using sensors or measuring instruments. These provide information about the river, which viscosity or the print. As a result, adjustments can be made to ensure a consistent and efficient furtherance to ensure.

Finally, it is important to maintain and clean the pump regularly to prevent deposits and blockages. This is particularly important when handling crushed raw materials, as they may be prone to deposits or clumps. Through a regular servicing The pump remains in optimal condition and ensures smooth operation.

The selection and use of the right pump is crucial for efficient and gentle handling of crushed raw materials. Through careful selection, regular maintenance and monitoring, companies can ensure that the raw materials are successfully processed by the production process promoted.

What role do pumps play for mashed raw materials?

Pumps play an important role in the mashing process. They make it possible for the mash to be effectively circulated and the starch to be optimally dissolved. They can also adjust the temperature in Mash boiler Maintain it consistently and thus ensure uniform mash quality. There are various types of pumps that can be used for the mashing process, such as centrifugal pumps or eccentric screw pumps. However, it is important that the pump meets the specific requirements of the mashing process to achieve the best possible result.

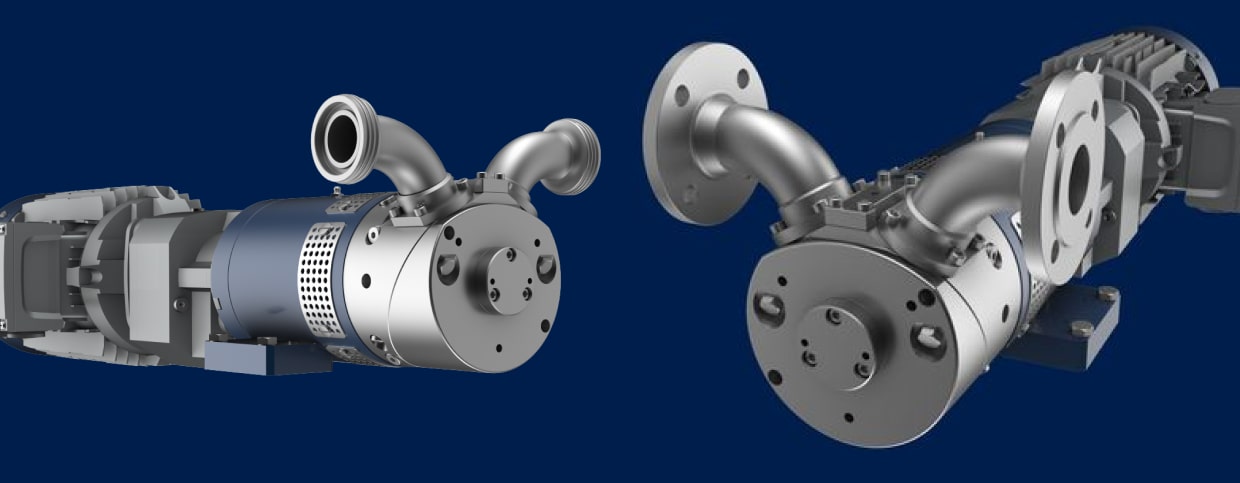

Die wobble ring pump Is a positive displacement pump, which is specifically designed for this type of application. It consists of a housing in which a rotor with eccentrically arranged rotary cams or rings is located. The wobble ring pump uses the wobble movement mechanism to capture the mashed mass and transport it through the system.

The way the wobble ring pump works is relatively simple. When the rotor rotates, the cams move along the inner wall of the housing and create a tumbling motion. This produces alternately printing- and vacuum zones in the pump head. When the rotor reaches a pressure zone, the mass is drawn into the pump. When the rotor reaches the vacuum zone, the mass is pumped through the pipe system.

The decisive advantage of the wobble ring pump when handling crushed raw materials lies in its ability to pump gently. Since it is a positive displacement pump, the mass is not crushed or compressed, which could lead to damage to the raw materials. Instead, the mass is gently grasped and conveyed, increasing its consistency and quality is retained.

Another example of the use of the wobble ring pump for crushed raw materials is the production of sauces and pastes in food industry. Mashed raw materials are often used in the production of sauces and pastes. The wobble ring pump also plays an important role here. Thanks to its gentle displacement function, it can efficiently and gently convey the viscous mass. It can also do this completely without affecting the consistency or quality of the raw materials. In this case, the wobbling ring pump is used to transport the mashed mass from the mixing containers into the processing machines. This ensures that the production process runs smoothly and that the raw materials are evenly distributed.

Overall, the wobble ring pump plays a decisive role in handling crushed raw materials in various industries. Thanks to its gentle and efficient conveying, it ensures high-quality processing of the raw materials. Be it in the brewery industry or at production From sauces and pastes, the wobble ring pump meets all your requirements. Regular maintenance and cleaning of the wobble ring pump is crucial to maintain its efficiency and prevent deposits. Thanks to the wobbling ring pump, mashed raw materials can be processed effectively and of high quality.