Application and function of pumps in the cosmetics industry

Cosmetic companies must constantly find new ways.

Where does the term cosmetics originate?

In the past, body jewelry or the decoration of our bodies has always played a major role. Die History of cosmetics It goes back a long way. As early as 5,000 years before Christ, the Romans, Egyptians and Greeks tried out body beautification. The function back then was to protect the body from solar radiation. They rubbed themselves with ointments and oil to smell good and put on makeup with powdered malachite, lead powder and cinnabar.

Even then, the ideal of beauty was constantly changing and already in the Middle Ages, the requirements for cosmetics were completely different. During the Middle Ages, washing got a bad reputation due to the influence of the church. The Church considered everything physical to be a sin. This view extended back to the Baroque period. Personal hygiene was very poor and this promoted illnesses. It became more on fragrances set which drown out body odors. Napoleon's wife finally brought the concept regular washing and personal hygiene back in fashion and revolutionized living standards and the cosmetics industry.

In the coming years, the cosmetics industry grew and became increasingly important to people.

In the 1980s, there was a major development in skin care. ingredients could now be sliced through the first layers of skin. That paved the way for the Anti-aging and was a milestone for the entire cosmetics and skincare industry. With the help of so-called liposomes ingredients can penetrate the skin and also have an effect there.

We are currently witnessing another change. cosmetic products Most of them now have a natural origin and the focus is on sustainability. Skin care and proper sun protection are also increasingly playing an important role.

The term cosmetics originated from the ancient Greek words Kósμμεkōkósós and Kósμω kosméo. That means as much as I decorate, I order or decorate myself.

About our pumps for the cosmetics industry

What does the cosmetics industry produce?

The main goal of cosmetic manufacturers Is that the production of substances , which are intended to beautify the human body. These substances come into contact with human skin, hair, fingernails and toenails and sometimes even teeth and mucous membranes of the mouth. that Field of application ranges from cleaning, perfuming or protecting, to embellishing or maintaining in good condition. Deodorants, for example, can even change human body odor.

Examples of products include nail polishes, makeup, body creams or shower gels . It also includes substances that protect us from external influences, such as sunscreen.

How are cosmetics made?

To understand how pumps work in the cosmetics industry, it is first important to understand how cosmetics are manufactured.

If you look at a very simple cream, for example, which consists only of its basic components, it contains both water and fat. With the help of a Emulsifiers Which part of the fat content is can water and grease mix. In addition to the emulsifier, the fat phase also contains a consistency agent and vegetable oils.

pumps in the cosmetics industry They must therefore be able to transport liquids and fats without any problems. In addition, they must be able to dose, mix, fill and temperature.

When conveying mascara, it must be possible to transfer the highly viscous mass of mascara from a large container into small mascara tubes.

It must be possible to dose fragrances and dyes evenly.

Like the example of mousse It is clear that should pumps proportional raw materials and, where appropriate, active substances to emulsions be able to mix.

cosmetic pumps pump even into small tubes and containers with precision.

Temperature control ensures heat recovery concepts and optimizes continuous processes.

In Germany, there are very strict guidelines on the requirements for cosmetic products and their production process . It is continuously checked on a random basis. In addition, you must ingredients be marked precisely, as is the Best before date . Manufacturers themselves must ensure that their products comply with all regulations. Since 2013, there have also been very strict rules regarding animal testing. In the European Union, there must be no more products on the market that have been tested on animals in any way.

You can find out more about this on the website of Federal Protection for Consumer Protection and Food Safety find.

Which substances are promoted in the cosmetics industry?

Depending on the desired end product, the substances which promoted must be and so must the manufacturing process. Solvents and surfactants are processed into skin cleansers, for example. Surfactants and moisturizers work really well for shaving gels or shaving cream. skincare products consist largely of fat components and care substances. UV filters are added to sunscreens. Titanium oxides are added to oral hygiene products and scented oils help with perfumes and substances with odors. Where appropriate, dyes and preservatives are also used in hair care products and swelling agents and thickeners for decorative cosmetics or body care products.

Which pumps are suitable for pumping cosmetic products?

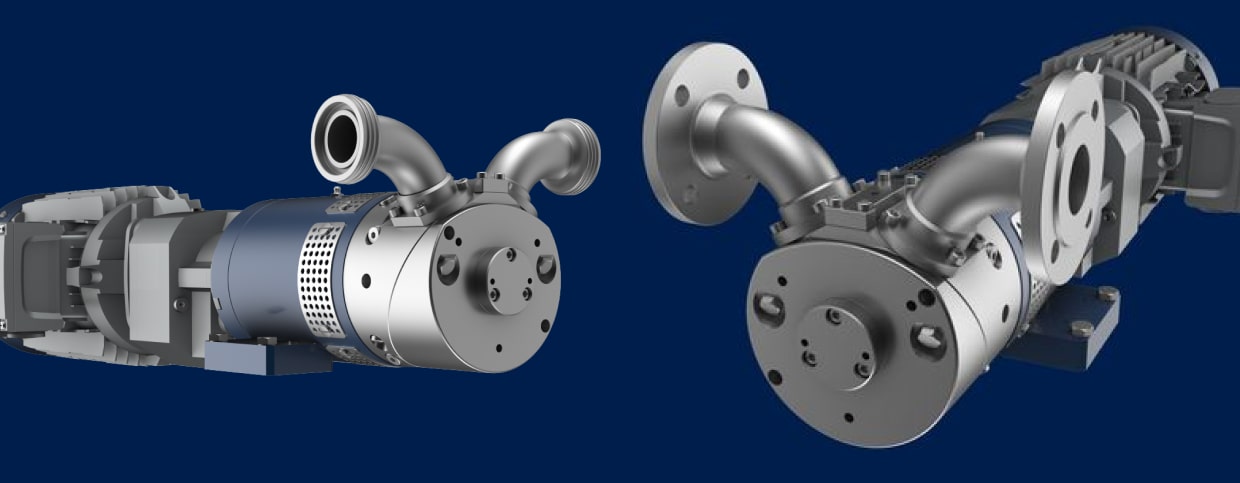

A good and uncomplicated solution is funding with rotary lobe pumps . Rotary lobe pumps maintain hygiene standards thanks to their contact-free operation. They are self-priming and valveless pumps and belong to the group of positive displacement pumps. Inside the rotary lobe pump, two rotary pistons rotate and thus generate a vacuum, which conveys the medium inwards and then outwards. Rotary lobe pumps are particularly suitable due to their low wear and the prevention of contamination during production cycle , very good for cosmetics manufacturers.

In addition, there are eccentric screw pumps very suitable. They also work with the suppression principle. These types of pumps work ideally for gentle conveying of highly viscous and even tough pumping media. They can work continuously or in batching. Eccentric screw pumps consist of a rotor, which rotates in the so-called stator. The resulting vacuum enables the pumping process. With this pump in particular, the flow rate depends on the size and speed of the pump.

But above all, the pump technology Our wobble ring pump is ideal for production process suitable for cosmetic products. Inside the wobble ring pump, there is an annular piston, which sits on a ball. This is oriented obliquely to the axis of rotation and is part of a rotating shaft. The ball and piston sit in the spherical pump housing. If the shaft now rotates, the desired wobbling movement occurs. This creates a vacuum, which sucks in the medium and transfers it to the pressure side of the pump. The pump is separated into the pressure and suction sides. Here too, careful conveying of highly viscous pumping media is required, especially in the cosmetics industry given.

You can find out more about our wobble ring pump on our webpage or in our Product brochure .

Here You can find more information about the application and functionality of diaphragm pumps.